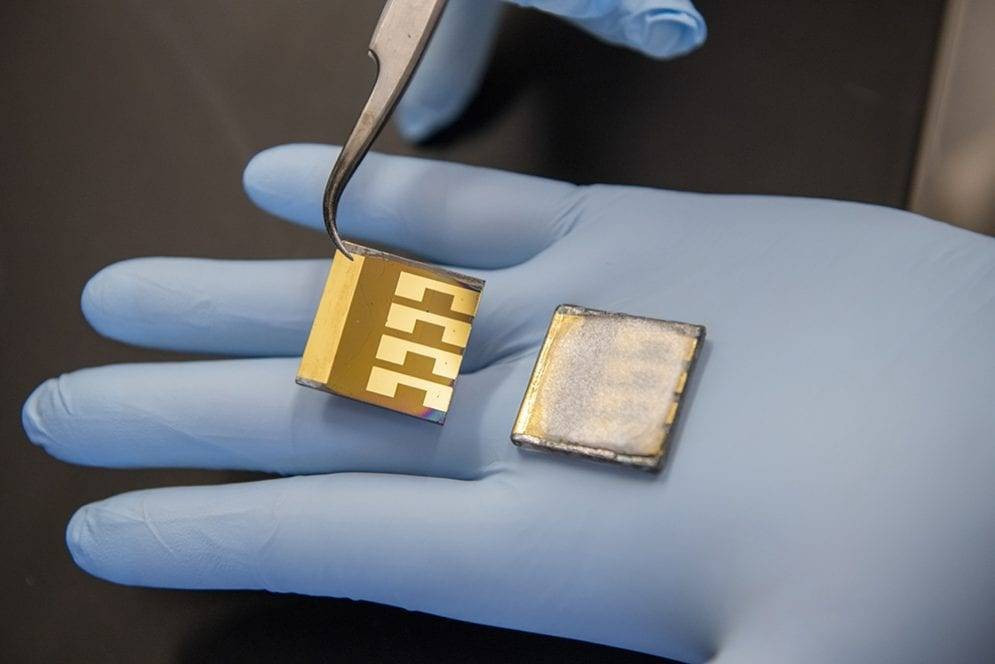

A recent breakthrough from researchers at KAUST, Fraunhofer ISE, and the University of Freiburg has pushed perovskite-silicon tandem solar cell efficiency to a record 33.1 percent on industry-standard textured silicon substrates. By applying a novel passivation layer—1,3-diaminopropane dihydroiodide—to the rough perovskite surface, the team enhanced fill factor and open-circuit voltage (2.01 V), outperforming previous flat-front results and laying a solid foundation for future improvements. This innovation not only boosts performance but aligns with existing manufacturing processes, significantly advancing the prospect of large-scale commercialization.

Sources: Cosmos Magazine, TechNews, SciTechDaily

Key Takeaways

– Record efficiency achieved with industry-compatible textures: By successfully passivating perovskite atop textured silicon—used widely in commercial panels—the team reached 33.1% efficiency, making this lab breakthrough more relevant to mass production.

– Passivation boosts both surface and bulk performance: The 1,3-diaminopropane dihydroiodide treatment improved not just surface properties but enhanced conductivity throughout the perovskite layer, boosting overall cell performance.

– Strong platform for future developments: This advance lays a theoretical and practical foundation for continual gains in tandem solar technology, with more efficient, scalable, and manufacturable designs to follow.

In-Depth

Wrap your mind around this: solar cell tech just got a serious upgrade—and it’s not just lab talk. Researchers over at KAUST, Fraunhofer ISE, and Freiburg have managed something remarkable—by treating a rough, textured silicon surface (the kind already used in factories) with a special passivation layer—1,3-diaminopropane dihydroiodide—they boosted a perovskite-silicon tandem solar cell to a stunning 33.1 percent conversion efficiency, with an open-circuit voltage of 2.01 volts.

What’s neat is that this approach isn’t just theoretical—it fits existing industrial silicon textures that already dominate the solar panel market. That makes this step far more practical than earlier attempts that only worked on smooth, flat surfaces. The passivation didn’t just fix up the surface: it improved conductivity throughout the perovskite layer, meaning better performance across the whole structure. That in turn improved the fill factor, making the cell more efficient overall.

Now, remember, silicon alone is nearing its theoretical max efficiency (~29–30 percent), so this leap is more than incremental—it’s a game-changer. Plus, the fact that this advance builds on existing silicon production lines highlights real commercial potential.

Bottom line: this isn’t just scientific hype. It’s a realistic path toward better, cheaper, more powerful solar panels. And given our energy needs, that’s the kind of progress we all welcome—light, practical, forward-moving.