MIT researchers have taken a big step forward in turning concrete from a passive building material into an active energy-storing element. Their latest development in electron-conducting carbon concrete (dubbed “ec³”) achieves a ten-fold gain in energy storage capacity over previous versions, enabling one cubic meter of concrete to store more than 2 kWh of energy—enough to power a refrigerator for a day. The advance comes from a deeper nanoscale understanding of the fractal-like carbon network inside the material, and optimizing both electrolyte composition and how it’s incorporated into the concrete mix. While conventional batteries still offer higher energy density, ec³ concrete offers a promising path toward embedding energy storage into walls, foundations, roads, and other infrastructure. This could support applications such as structural health monitoring (since stress could alter the electrical output), off-grid homes, smart infrastructure, and even roads or parking pads that charge electric vehicles. The researchers published their findings in PNAS.

Key Takeaways

– The new ec³ concrete achieves ~10× the energy capacity of earlier versions, reaching over 2 kWh per cubic meter—shrinking the volume required to power a home from ~45 m³ to ~5 m³.

– The breakthrough relies on imaging and mapping the carbon network at the nanoscale, and optimizing electrolyte integration (including organic salts) to improve charge transfer.

– Embedded energy-storing concrete offers applications beyond mere power storage: structural health sensing, distributed energy storage, and infrastructure that double as power-generating or power-transmitting elements.

In-Depth

For decades, concrete’s role has been structural: foundations, walls, roads. But MIT researchers and collaborators are pushing it into the energy realm. Their ec³ (electron-conducting carbon concrete) blends cement, water, ultra-fine carbon black, and electrolytes to create a conductive nanonetwork that can both support load and act as a supercapacitor. The recent development increases energy density by tenfold, making the notion of building-scale energy storage far more practical.

At the heart of this advance lies a meticulous look into how the carbon black particles connect inside concrete. Using techniques like FIB-SEM tomography, the team cut away nanoscale layers, imaged them, and reconstructed the conductive “web” that threads through the pores of concrete. That web has a fractal, branching architecture which allows electrolyte ions to permeate deeply and reduces resistance. With that insight, the researchers were able to adjust the electrolyte chemistry and how it’s introduced (for example, mixing it into the concrete rather than soaking cured material) to enhance storage performance. One key electrolyte combo uses quaternary ammonium salts (commonly found in disinfectants) dissolved in organic solvents like acetonitrile, yielding high conductivity and stability.

With these optimizations, one cubic meter of ec³ can now store just over 2 kWh—comparable to powering a refrigerator for a full day. While that doesn’t match lithium-ion batteries in energy density, the real selling point lies in integration: walls, slabs, pillars—all could store energy without taking room or requiring retrofitting. In previous versions, powering a home’s daily use would require ~45 m³ of ec³; now that drops to ~5 m³, equivalent to a wall’s volume. This opens the door to embedded energy storage in homes, bridges, roads, and parking areas, especially combined with solar or EV infrastructure.

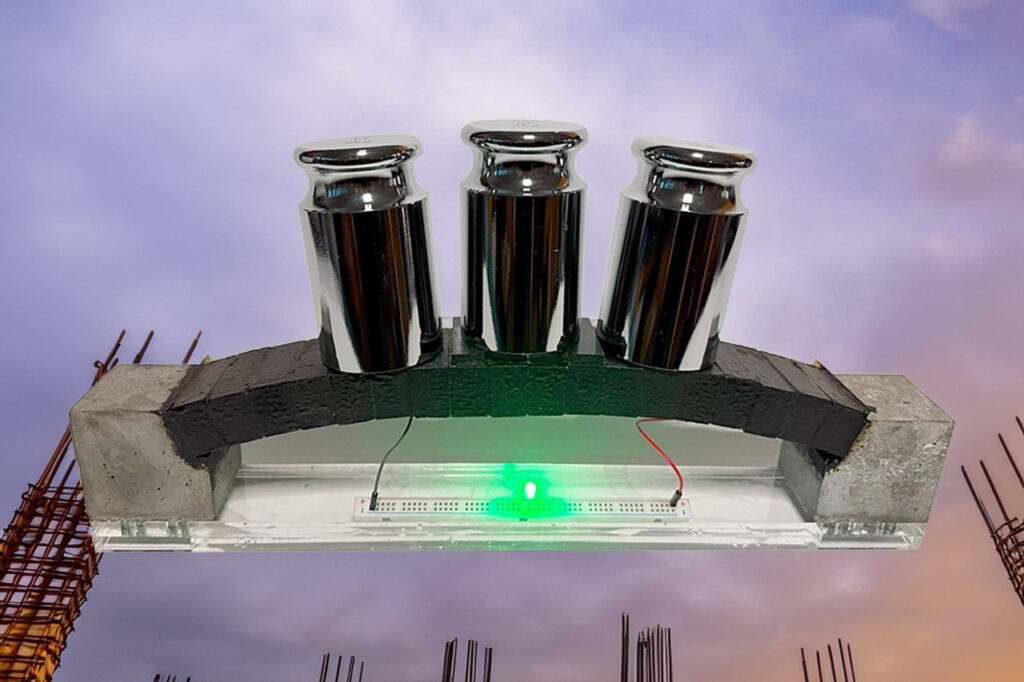

One fascinating side effect: when the team built a miniature ec³ arch that bore load, they found that tightening load caused the LED the arch powered to flicker. That suggests that mechanical stress might influence electrical contact, allowing the material to self-sense structural strain or damage. In other words, buildings made with ec³ might one day monitor their own health in real time.

Still, challenges remain. Though improved, ec³’s energy density is lower than state-of-the-art batteries, and scaling this from lab to large structures raises manufacturing, durability, and economic questions. Also, long-term stability, weather effects, cycling losses, and safety in extreme conditions must be tested. But the promise is compelling: infrastructure that does more than hold us up—it powers us, senses us, and perhaps helps grids balance intermittency. As we push toward renewable energy reliance, tools like ec³ could become foundational in both literal and metaphorical senses.